Our automatic broaching machine can be planned by client requirements to foster a completely encased programmed stacking and dumping proposing focus, which comprises a stacking framework, a transport line, a dumping framework, and an introducing machine. Our broaching machine can be associated with other machines for the online investigation. Subsequently, the working surface is low, and there is a compelling reason to need to make pits. The machining apparatus is outfitted with a programmed chip brushing system like a programmed turning chip brushing component can likewise be chosen by client necessities to draw out the assistance life of the device.

Advantages of using the different categories of automatic broaching machines over the setting process

A. Fully automatic servo pull-down broaching machine

The Fully automatic servo pull-down is broaching machine consisting of a good level of structure. Like it consists of its making with the help of screw rods, imported guides, and bearings from other countries. Such level of working of these broaching machines is reliable and has a good level of efficiency. The machine will also not make large noise as it consists of a vibrating plate that will help feed. And it will test all types of products with its automatic operation.

1. Model CCLC-5T-ZDXL

The pulling force of the machine model CCLC-5T-ZDXL is 50, which works with the level of maximum stroke of 800. At the same time, the machine’s cutting speed is 1-8 m per minute. And the full height and weight of the machine is 4000 mm.

However, the machine will work with a floor space of 1500X3000. Its returning speed is only 15 consisting of the 3.5 its net weight.

2. Model CCLC-10T-ZDXL

The pulling force of the machine model CCLC-10T-ZDXL is 100, which works with the level of maximum stroke of 1000. At the same time, the machine’s cutting speed is 1-8 m per minute. And the full height and weight of the machine is 4500 mm.

However, the machine will work with a floor space of 1500X4000. Its returning speed is only 15, consisting of 4.5 of its net weight.

3. Model CCLC-15T-ZDXL

The pulling force of the machine model CCLC-15T-ZDXL is 150, which works with the level of maximum stroke of 1200. At the same time, the machine’s cutting speed is 1-8 m per minute. And the full height and weight of the machine is 5000 mm.

However, the machine will work with a floor space of 2500X4500. Its returning speed is only 15 consisting of eight of its net weight.

B. Dual ram automatic vertical pull-down broaching machine

The automatic broaching machine will perform its work for the drying, cleaning, and another level of stain removal things. Where there is a surfacing process, these machines will best suit the presence of the stains. One can use this automatic machine on a heavy-duty surface. Like the machine will never compromise with the working level and efficiency of the work.

You can also use these machines to diversify the different levels of tables and jigs. And this machine will help maintain the work for a good period.

1. Model CCLC-ST-SF/2

The pulling force of the machine model CCLC-5T-ZDXL is 50, which works with the level of maximum stroke of 800. At the same time, the machine’s cutting speed is 1-8 m per minute. And the full height and weight of the machine is 3000 mm.

However, the machine will work with a floor space of 1500X3000. Its returning speed is only 20, consisting of five of its net weight.

2. Model CCLC-10T-SF/2

The pulling force of the machine model CCLC-5T-ZDXL is 100, which works with the level of maximum stroke of 1200. At the same time, the machine’s cutting speed is 1-8 m per minute. And the full height and weight of the machine is 4500 mm.

However, the machine will work with a floor space of 1500X3000. Its returning speed is only 20, consisting of the 10 in its net weight.

C. Dual ram vertical helical spline broaching machine

1. Model CCLC-LX-T5-ZD

The pulling force of the machine model CCLC-LX-T5-ZD is 50, which works with the level of maximum stroke of 1000. At the same time, the machine’s cutting speed is 0- 10 m per minute. And the full height and weight of the machine is 4000 mm.

However, the machine will work with a floor space of 1800X3000. Its returning speed is only 20 consisting of 5 of its net weight.

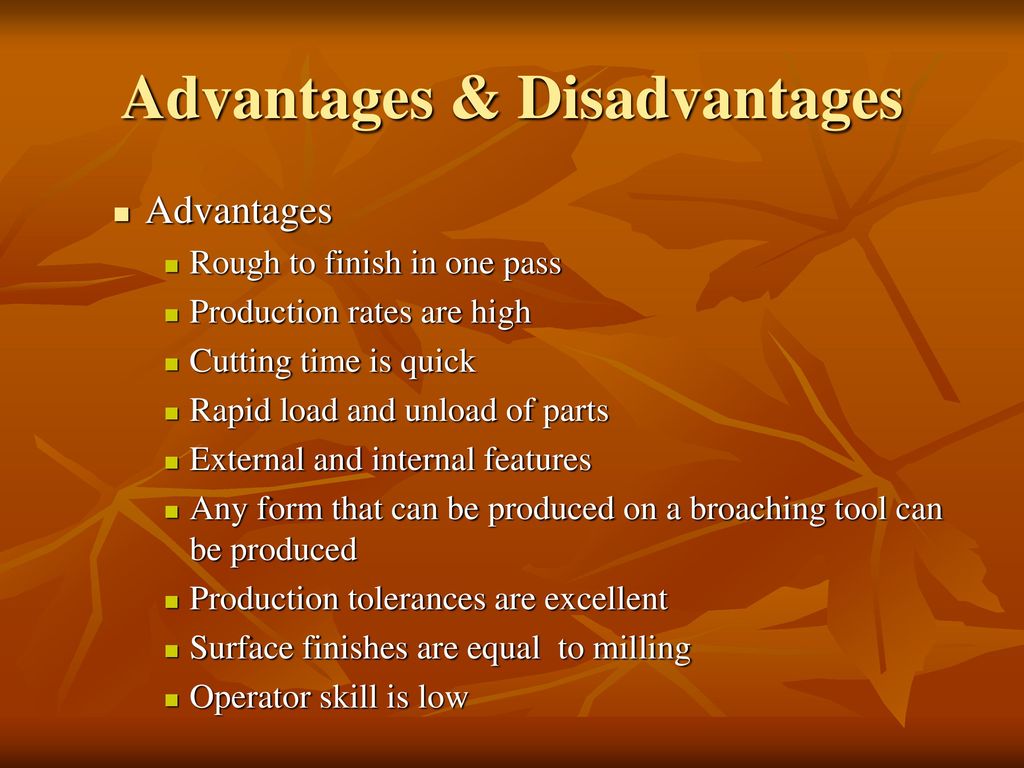

Main benefits of broaching machine

1. Creation level

A suggesting machine is a machine that will offer you a decent degree of creation. Further, it likewise guarantees a high creation level contrasted with different machines and the quality. Furthermore, such a machine will likewise be viewed as best for the large-scale manufacturing with a decent monetary status.

2. Exactness rate

The working of a machine isn’t just adequate when you see it. Yet, one additionally guarantees the exactness you will get just from the broaching machine. The machine will assist you with making the last little detail to the items you won’t get from ordinary machines. Notwithstanding, such machines will likewise assist with getting a solitary stroke with a similar shaper level.

Conclusion

Without much of a stretch, you can perceive how these various classifications of proposing machines will improve your work. Like you can play out numerous functions with these machines, costing just a limited quantity. Each of the various classes of suggesting machines will show their activities to the client, which will keep the client in contact with these automatic broaching machines. Get all your suggesting machines from our organization as it won’t ever let you have an opportunity of grievance.